Flour mill equipment screw conveyor

In flour mills, screw conveyors are often used for conveying materials. They are conveying machines that rely on rotating spirals to push bulk materials for horizontal movement or inclined conveyance.

TLSS series screw conveyor has the characteristics of simple structure, compact, reliable operation, convenient maintenance, good sealing, can be fed or unloaded over the entire working length, and can be transported in two directions in the same casing. Suitable for conveying powdered materials and granular materials.

TLSS series screw conveyor is mainly composed of screw shaft, machine slot, hanging bearing and transmission device. The spiral body is welded by spiral blades and a mandrel. The active transmission shaft is a seamless steel tube. The conveying length can be set according to demand.

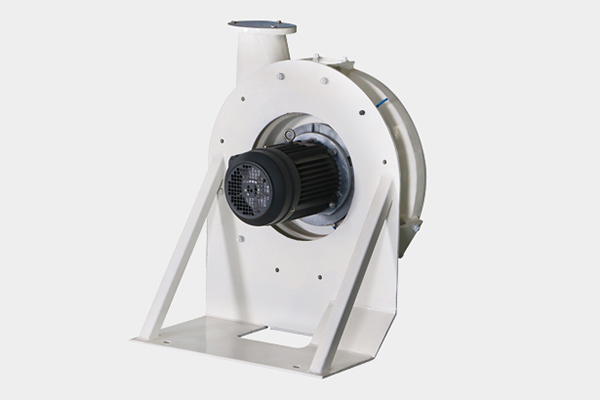

Impact Detacher machine for flour mill

The FSLZ series Impact Detacher is mainly used as auxiliary supplementary equipment in the flour blending system to impact the materials to loosen the flour and effectively increase the sieving rate.

The machine is mainly composed of feed inlet, stator disk, rotor disk, casing, motor and other parts. The outlet is set in the tangential direction of the casing and is connected to the pneumatic conveying pipeline. The material enters from the central inlet of the machine and falls on the high- speed rotating rotor disk. Due to the centrifugal force, the material is violently between the stator and the rotor pin. After impact, it is thrown to the shell wall, the flakes are broken due to strong impact, and sprayed with the air flow in the shell to the discharge port to complete the flour loosening process.

Purifier in Flour mill

The Purifier is an indispensable equipment in the flour mill. It uses the combined action of sieving and air flow to screen the flour.

The feeding material uses the vibration of the feeding device to make the material cover the entire screen width. Relying on the vibration of the screen body, the material is moving forward and layered through the screen surface and distributed on the three-layer screen. Under the combined action of vibration and air flow, the material is classified and layered according to the different particle size, specific gravity and suspension speed.

During the flour purifing process, the negative pressure air flow passes through the material layer, sucking out the debris of low specific gravity, the larger particles are pushed forward to the tail of the screen, the smaller particles fall through the screen, and the material passing through the screen is collected In the material conveying tank, the different materials that are sieved pass through the material conveying tank and the material discharging box, and are discharged according to the requirements of the process.

Post time: Mar-10-2021