-

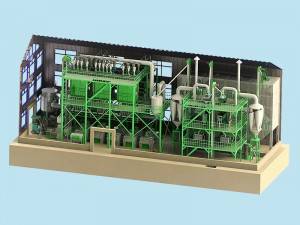

20-30 Ton Per Day Small Flour Mill

Small flour mills can process a variety of grains, such as wheat, corn, beans, etc. the flour can be used to make cakes, steamed bread, feed, etc. The color of the flour powder produced is white, free of impurities, has high protein content, moderate gluten strength, and the finished product is soft and delicious.

-

Corn Mill Plant

CTCM-series Compact Corn Mill , can mill corn/maize, sorghum, soybean, wheat and other materials. This CTCM-series Compact Corn Mill adopts wind power lifting, roll grinding ,combining with sifting together, thus gain the ability of of high productivity, well powder lifting, no flying dust, low power consumption, easy to maintenance and other good functions

-

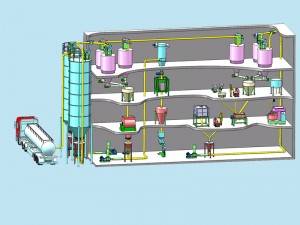

Flour Blending Project

The powder blending section generally has the functions of powder blending and powder storage.

-

Wheat Flour Mill Plant

This set of equipment realizes automatic continuous operation from raw grain cleaning, stone removal, grinding, packing and power distribution, with smooth process and convenient operation and maintenance. It avoids the traditional high-energy consumption equipment and adopts new energy-saving equipment to minimize the unit energy consumption of the whole machine.

-

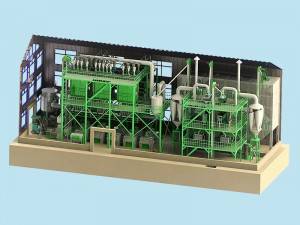

Compact Corn Mill

CTCM-series Compact Corn Mill , can mill corn/maize, sorghum, soybean, wheat and other materials. This CTCM-series Compact Corn Mill adopts wind power lifting, roll grinding ,combining with sifting together, thus gain the ability of of high productivity, well powder lifting, no flying dust, low power consumption, easy to maintenance and other good functions

-

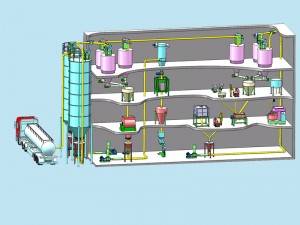

Compact Wheat Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

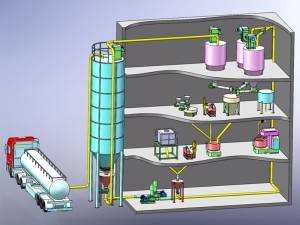

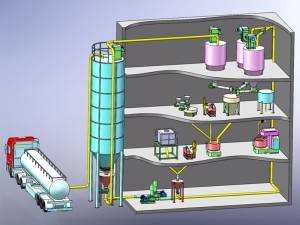

Big capacity wheat flour mill

These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5 to 6 storey high (including the wheat silo, flour storage house, and flour blending house).

Our flour milling solutions are mainly designed according to the American wheat and Australian white hard wheat. When milling a single kind of wheat, the flour extraction rate is 76-79%, while the ash content is 0.54-0.62%. If two kinds of flour are produced, the flour extraction rate and ash content will be 45-50% and 0.42-0.54% for the F1 and 25-28% and 0.62-0.65% for the F2. Specifically, the calculation is based on the basis of dry matter. The power consumption for the production of one ton of flour is no more than 65KWh on normal conditions.

-

Flour Blending

First, the different quality and different grades of flour produced in the milling room are sent to different storage bins through conveying equipment for storage.

-

TCRS Series Rotary Separator

Widely used in farms, mills, cereals shops and other grain processing facilities.

It is used to remove light impurities such as chaff, dust and others, fine impurities such as sand, small weed seeds, small chipped grains and coarse contaminants such as straw, sticks, stones, etc. from the main Grain. -

TQSF Series Gravity Destoner

TQSF series gravity destoner for grain cleaning, To remove stone, To classify grain, To remove light impurities and so on.

-

Vibro Separator

This high performance vibro separator, together with the aspiration channel or recycling aspiration system is widely used in flour mills and silos.

-

Rotary Aspirator

Plane rotary screen is mainly used for cleaning or grading raw materials in milling, feed, rice milling, chemical industry and oil extraction industries. By replacing different meshes of sieves, it can clean impurities in wheat, corn, rice, oil seed and other granular materials.

The screen is wide and then flow is big, cleaning efficiency is high, flat rotation movement is stable with low noise. Equipped with aspiration channel, it performs with clean environment.