Flour Blending

Brief Introduction:

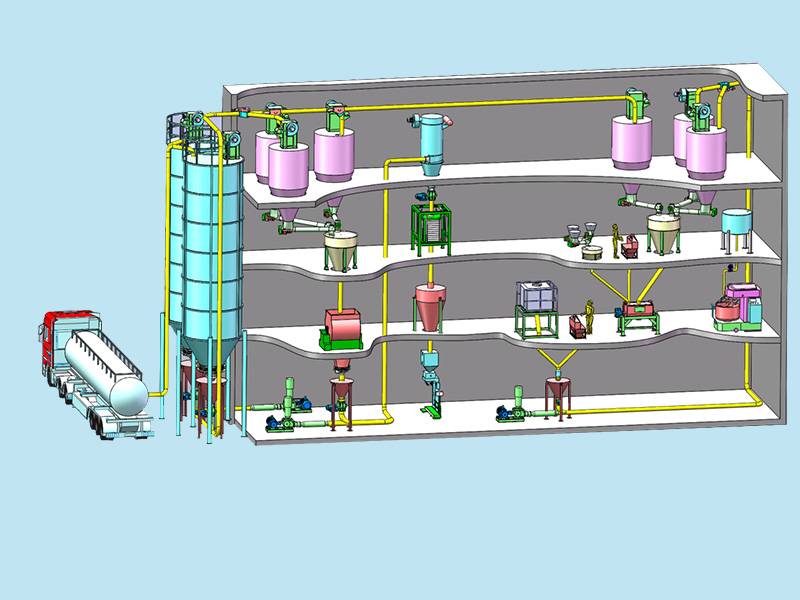

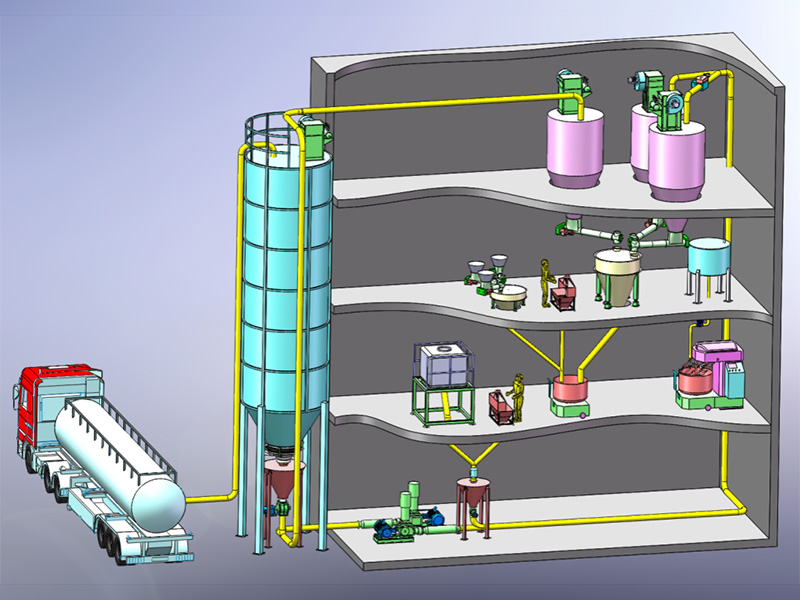

First, the different quality and different grades of flour produced in the milling room are sent to different storage bins through conveying equipment for storage.

Product Detail

Product Tags

First, the different quality and different grades of flour produced in the milling room are sent to different storage bins through conveying equipment for storage. These flours are called basic flour. Before the basic powder enters the warehouse, it must go through the procedures of flour inspection, metering, magnetic separation, and insecticide. When mixing flour is needed, the basic flours of several varieties that need to be matched are discharged from the bin, mixed together according to a certain proportion, and various additives are added as needed, and the finished flour is formed after stirring and mixing. Based on the differences of various types of basic flour, different ratios of various basic flours, and different additives, different grades or different types of special flour can be mixed and realized.

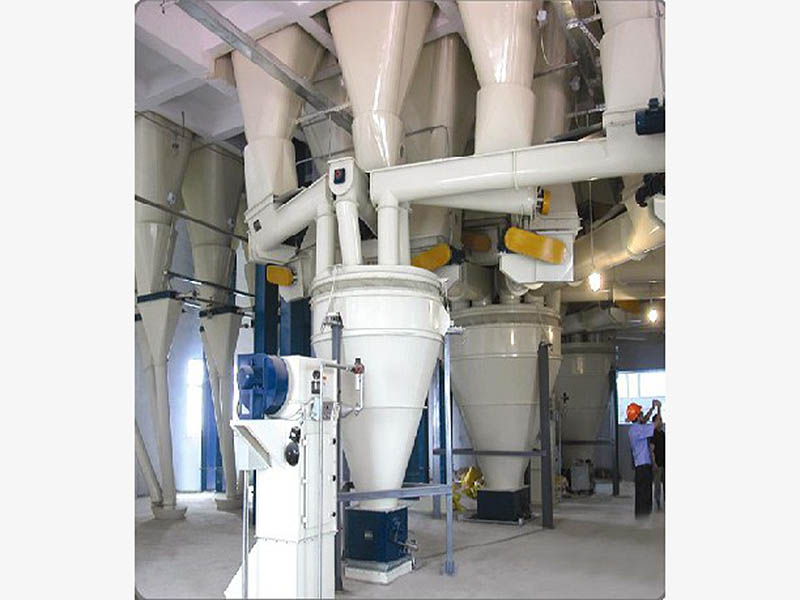

Flour Blending equipment

Vibro Discharger

Micro Feeder

Positive Pressure Airlock

Two Way Valve

Inserted High Pressure Jet Filter

Low Pressure Jet Filter

Tubular screw conveyor

Flour Batch Scale

Application of Flour Blending(food deep processing industry)

This system includes the pneumatic conveying and storage of bulk powder, ton powder and small package powder. It adopts PLC + touch screen to realize automatic weighing and powder distribution, and water or grease can be added accordingly, which reduces labor and avoid dust pollution.

Flour Blending Cases

The Flour Blending workshop of the flour mill mixes the flour in different flour bins in proportion to ensure the stability of the final product.

The Flour Blending workshop of the flour mill mixes different types of flour in proportion to produce different types of functional flour, such as dumpling flour, noodle flour, and bun flour.

The production workshop of the noodle factory adopts an all-stainless steel powder bin and batching scale. The flour in the bulk powder bin is pneumatically conveyed to the batching scale for accurate measurement, which saves the process of manual unpacking and avoids the situation that workers add wrong amount of flour.

In the Flour Blending workshop of the noodle factory, several ingredients are added quantitatively to the flour to produce different varieties of noodles.

The Flour Blending workshop of the biscuit factory adds several ingredients to the flour quantitatively. It is made of all stainless steel and is food-grade anti-corrosion.

In the production workshop of biscuit factory, the flour would enter the dough mixer for mixing after being weighed and blended.

Packing & Delivery

>

>

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur