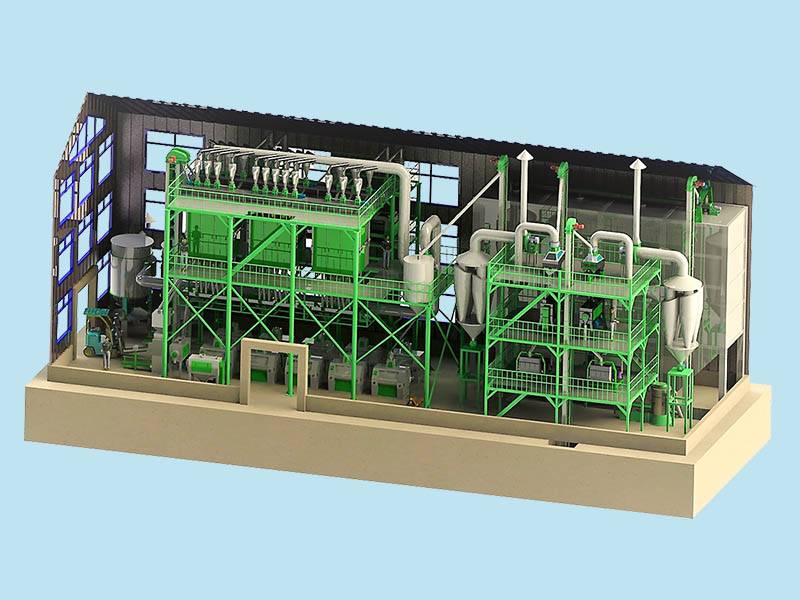

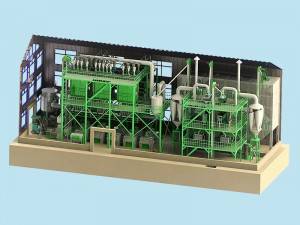

Compact Wheat Flour Mill

Brief Introduction:

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

Product Detail

Product Tags

Product video

Product Description

CLEANING SECTION

.jpg)

In the cleaning section,we adopt drying type cleaning technology.it normally includes 2 times sifting,2 times scouring,2times de-stoning,one time purifying,4 times aspiration,1 to 2 times dampening,3 times magnetic separation and so on.In the cleaning section,there are several aspiration systems which can reduce the dust spray-out from the machine and keep a good working environment.This is a complicated thorough flow sheet which can remove most of the coarse offal,middle size offal and fine offal in the wheat.The cleaning section is not onley suitable for wheat imported with lower moisture and but also suitable dirty wheat from local customers.

MILLING SECTION

.jpg)

In the milling section,there are four types of systems to mill the wheat to flour.They are 4-Break system,7-Reduction system,1-Semolina system and 1-Tail system.Purifiers are specially designed to get more pure semolina sent to the Reduction which improves the flour quality by a large margin.The rollers for Reduction,Semolina,and Tail systems are smooth rollers which are well blasted.The whole design will insure less bran mixed into the bran and the flour yield is maximized.Because the well designed pneumatic lifting system,the whole mill material is transferred by High pressure fan.The milling room will be clean and sanitary for aspiration adoption.

All the packing machines are automatioc.The packing machine has features of high measuring accuracy,fast packing speed,reliable and stable working.It can weigh and count automatically,and it can accumulate weight.The packing machine has function of fault self-diagnosis.It’s sewing machine has automatic sewing and cutting function.The packing machine is with sealed type bag-clamping mechanism,whih can prevent material from leaking out.The packing specification includes 1-5kg,2.5-10kg,20-25kg,30-50kg.The clients can choose different packing specification according to requirements.

In this part,we will supply electrical control cabinet,signal cable,cable trays and cable ladders,and other electrical installaton parts.The substation and motor power cable is not included except customer specially required.PLC control system is an optional choice for customer.In PLC control system,all the machinery is controlled by Programmed Logical Controller which can insure the mahinery running stably and fluently.The system will make some judgments and do reaction accordingly when any machine is in fault or stopped abnormally.In the same time it will alarm and remind the operator to settle the faults.Schneider series electrical parts are used in out electrical cabinet.The PLC brand will be Siemens,Omron,Mitsubishi and other international Brand.The combination of a good designing and reliable electrical parts insures the whole mill running smoothly.

TECHNICAL PARAMETER LIST

| Moded | Capacity(t/24h) | Roller Mill Moded | Sifter Model | Space LxWxH(m) |

| CTWM-40 | 40 | Manual | Twin Sifter | 30X8X11 |

| CTWM-60 | 60 | Manual | Twin Sifter | 35X8X11 |

| CTWM-80 | 80 | Pneumatic | Plan Sifter | 38X10X11 |

| CTWM-100 | 100 | Pneumatic | Plan Sifter | 42X10X11 |

| CTWM-120 | 120 | Pneumatic | Plan Sifter | 46X10X11 |

| CTWM-150 | 150 | Pneumatic | Plan Sifter | 50X10X11 |

Packing & Delivery

>

>