-

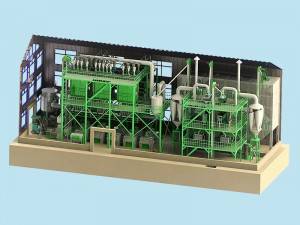

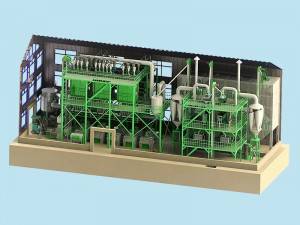

Chinese wholesale Big Wheat Flour Mill for Wheat Flour Price in Russia

These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5 to 6 storey high (including the wheat silo, flour storage house, and flour blending house).

Our flour milling solutions are mainly designed according to the American wheat and Australian white hard wheat. When milling a single kind of wheat, the flour extraction rate is 76-79%, while the ash content is 0.54-0.62%. If two kinds of flour are produced, the flour extraction rate and ash content will be 45-50% and 0.42-0.54% for the F1 and 25-28% and 0.62-0.65% for the F2. Specifically, the calculation is based on the basis of dry matter. The power consumption for the production of one ton of flour is no more than 65KWh on normal conditions.

-

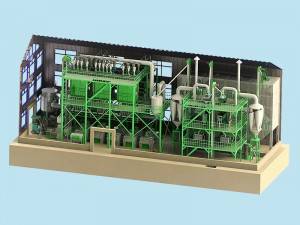

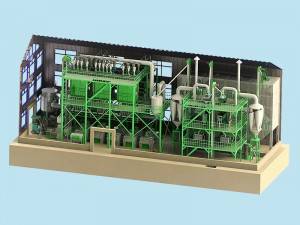

Discountable price Modern Wheat Maize Corn Grain Flour Semolina Posho Milling Mill

These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5 to 6 storey high (including the wheat silo, flour storage house, and flour blending house).

Our flour milling solutions are mainly designed according to the American wheat and Australian white hard wheat. When milling a single kind of wheat, the flour extraction rate is 76-79%, while the ash content is 0.54-0.62%. If two kinds of flour are produced, the flour extraction rate and ash content will be 45-50% and 0.42-0.54% for the F1 and 25-28% and 0.62-0.65% for the F2. Specifically, the calculation is based on the basis of dry matter. The power consumption for the production of one ton of flour is no more than 65KWh on normal conditions.

-

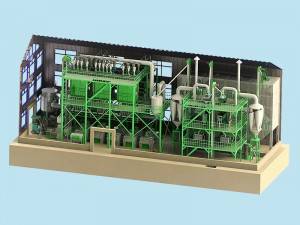

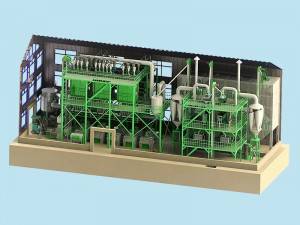

Professional China Africa PLC 150t/24h Wheat Flour Mill Machine with Stainless Steel

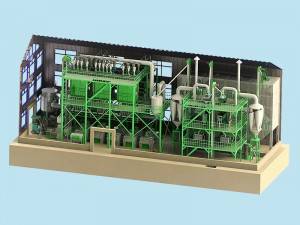

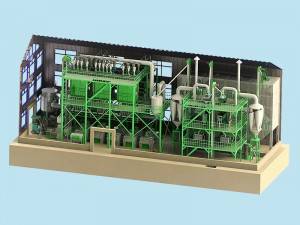

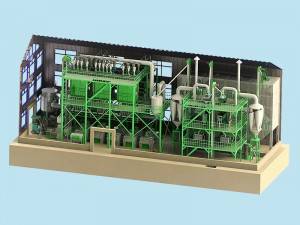

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

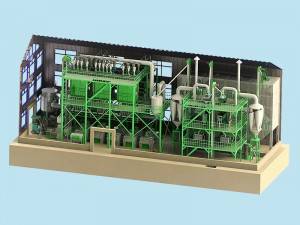

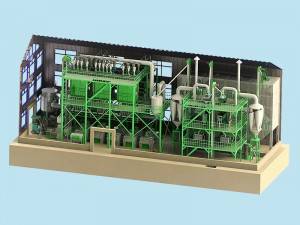

factory Outlets for China Good Quality Beater Flour Detacher for Wheat Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

Factory Customized Wheat Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

Hot sale Corn Milling Equipment Wheat Milling Machine Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

Best-Selling Farming Use Rice Milling Machine Maize Grinding Wheat Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

Hot-selling China Compact Automatic European Standard Quality Wheat Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

China Factory Small Wheat Flour Milling Mill Price

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

China High Efficient Corn Grinder Wheat Flour Grain Grinding Mill Crushing Machine

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

China Cheap price Small Wheat Flour Milling Mill Price

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

-

Supply OEM China MMT Wheat Flour Mill

The Flour Mill Equipment of Compact wheat flour mill machine for the whole plant are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers’ investment. The milling technology can be adjusted to satisfy customers’ different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.