High Quality Vibro Discharger

Brief Introduction:

High Quality Vibro Discharger to discharge materials from bin or silo without being choked by the vibration of the machine.

Product Detail

Product Tags

Product video

Product Description

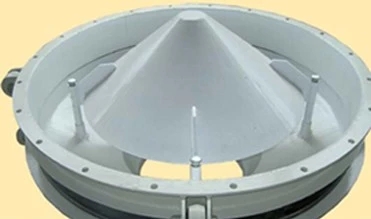

Flour Mill Machinery High Quality Vibro Discharger

High Quality Vibro Discharger to discharge materials from bin or silo without being choked by the vibration of the machine. Installed under the dampened wheat bins, flour bins, bran bins for the materials being discharged continuously.Can also be used under the big hopper.

Our vibro discharger is quite reliable and stable. It can discharge various granular and powdery materials evenly, stably and accurately.

The working noise of this hopper discharge equipment is quite small, and the energy consumption is low. Its production capacity is adjustable.

Our TDXZ series vibro discharger is a newly developed material discharging machine. It can be widely used for material discharging in industries like flour, cement, medicine, and so on.

Working principle

This machine is installed under the flour bin/silo bottom, for discharging materials uniformly with the motion of vibrating. Materials flow down to the discharging hopper and then under the vibration of motor, materials will flow through discharging plate evenly and gradually without being blocked.

Features

1. Our vibro discharger is quite reliable and stable. It can discharge various granular and powdery materials evenly, stably and accurately.

2. The working noise of this hopper discharge equipment is quite small, and the energy consumption is low. Its production capacity is adjustable.

3. The size of our vibrating bin discharger is quite small so that little space in needed for the installation.

4. The vibro discharger is available in several types which are suitable for bins in different diameters.

5. Stainless steel clamps are also provided.

6. Discharging plat taper: 30° for flour and 55° for bran.

7. Vibrate motor can be adjusted to meet various vibration force requirements.

8. Chromed clamps and wear resistant sleeve.

9. Discharge flour equably and continuously.

Discharging Disk

Conical discharging disk locates at the center part of discharging hopper, it pushes the material discharging slowly and uniformly from outlet, meanwhile, it can prevents the material from blocking.

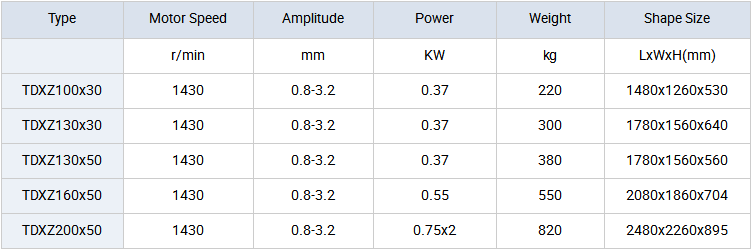

Technical Parameter List:

Packing & Delivery