Product Description

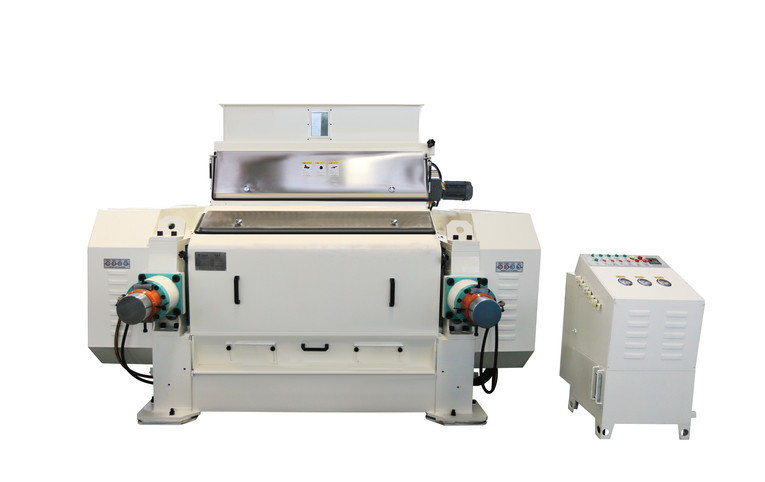

YYPYFP Series Pneumatic Roller Mill

YYPYFP series pneumatic roller mill compact structure with high strength, stable performance and low noise, operation is convenient with easy maintenance and low failure rate.

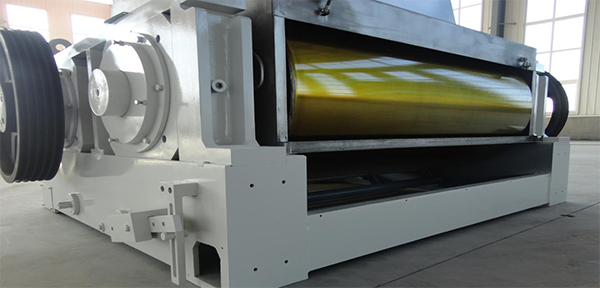

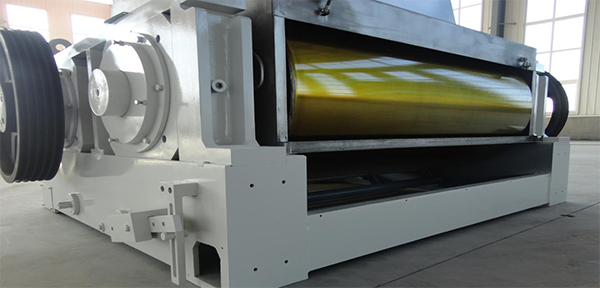

1.Roller

It adopts high-nickel-chromium-molybdenum alloy centrifugal roll from China First Heavy Industries with hardness of HS75º-78ºand thickness 30mm, which ensures the strength of roller’s inner support. the roller body is with a filling hole for adding heat conduction oil, which promise uniform heat recycling and the roll body will not deform. And the rolled flake is uniform, the roller service life is prolonged to be twice.

.png)

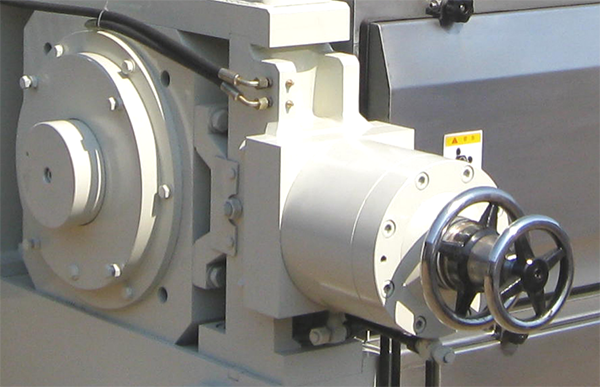

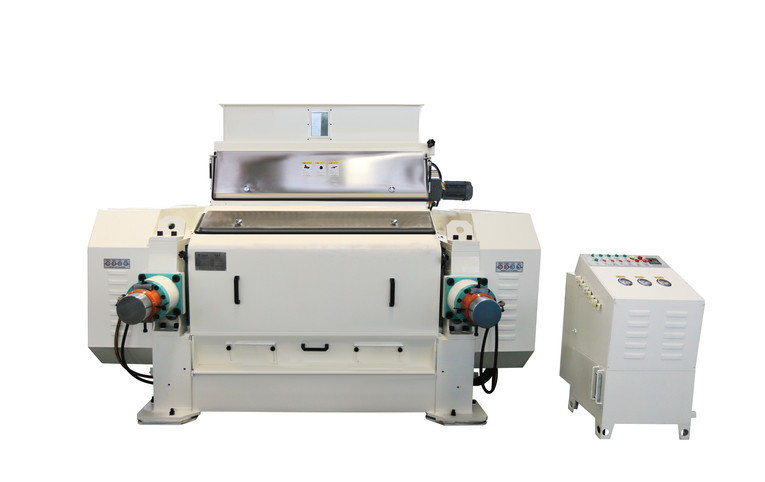

2.Bearing seat

Square bearing seats for rollers can move along the smooth rail, getting the two rollers engaged or disengaged, which is controlled by energy-saving PLC oil pump station.Equipped with SKF bearings, SEW geared motors, Siemens high-efficiency energy-saving motors.

.png)

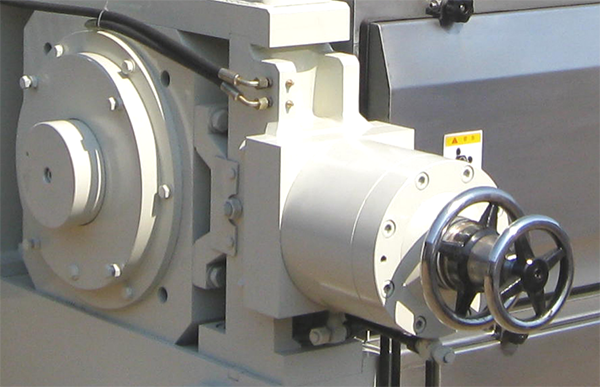

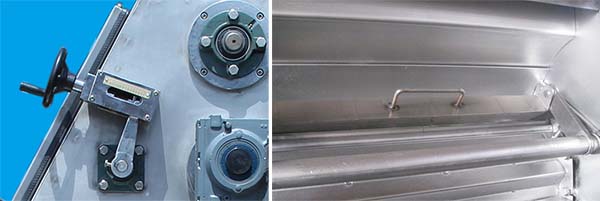

3. Location limit control

The location limit control is designed to avoid collision of the two rollers; The specially designed big and small hand wheels working together fulfills this purpose.With this design, the equipment is easier to operate, controlling is more precise and flaking is more stable.

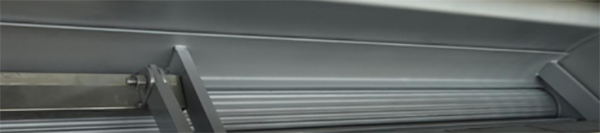

4. Feeding system

The speed of the toothed feeding rollers is controlled by a converter, ensuring feeding evenly along the roller.

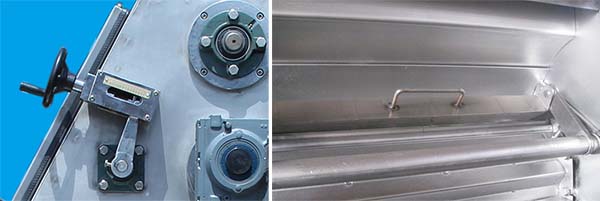

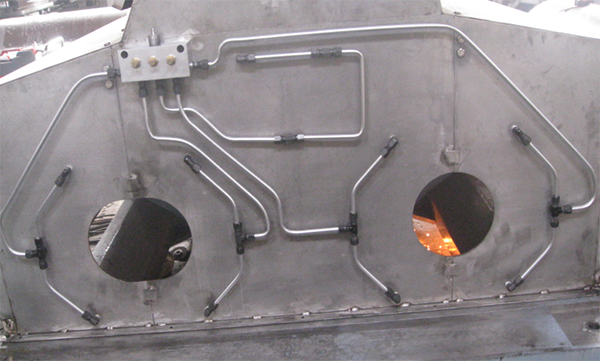

5. Blocking device

Its swaying is controlled by oil piston, fulfill the purposes of blocking or discharging materials; Slight adjusting depends on the calibration, which give two advantages: one is that the oil piston is strong enough to block materials efficiently, and the other is that referring to the calibration, hand wheel can give precise slight adjustment, very easily.

6. Magnetic separating device

Equipped with permanent magnetic bar to prevent damage to the roll from iron in the material; The magnetic bar can be set outside the feeder when it needs cleaning, this way makes cleaning easy and the iron scrap will not fall inside machine.

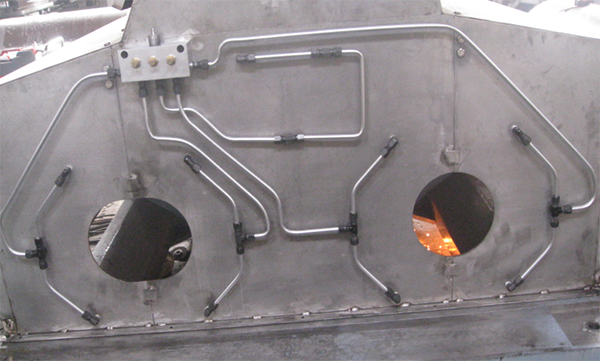

7. Inner pneumatic cleaning system

Compressed air is brought in to blow and clean the parts intermittently where materials accumulated. According to the quantity of materials accumulated, the pneumatic valve can be adjusted properly to keep the machine clean inside.

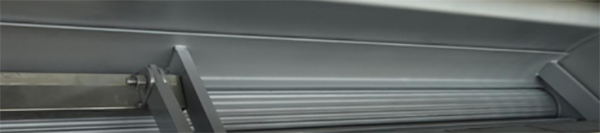

8. Outer scraper

The scraper is fixed on the base frame by means of spline shaft, and operates can adjust it outside the machine, very convenient; A location limit is designed for the scraper, and after scraper reaching to the right location, it barely wears out any more, which lengthen its work life largely; It can be pulled out along smooth rail when it needs replacing, quite simply.

9. Pointed blocking plate

It is casted and can keep working for several years without wearing out; operators can move it up, down, left and right freely outside the machine, ensuring no leakage of small particles.

10. Intermittent pumping station

The pumping station complete with PLC control system works in an intermittent way. It works like this, when the system pressure rises to the upper limit, the oil pump stops automatically to keep a proper pressure; and when the pressure falls under the lower limit, the oil pump automatically starts and increases the pressure back to normal in 2 or 4 seconds.

Comparing to the traditional pump station, the intermittent type has some advantages:

keeping the proper pressure for a much longer time, saving energy obviously; the real working time of the pump is quite short, so it has a longer work life than traditional type; Working in the intermittent way can keep case and oil temperature almost constant without rising too high, so the system is more stable than the traditional type;

11. Reliable transmission device

The machine equipped with double motors which run the fixed roller and the mobile roller by means of a narrow V type belt, twice more efficient than traditional C type belt, ensuring it working stably;

The pulley is standard WOT type, equipped with a taper sleeve for fast replacement, easy for installation and matainance;

Beside, each set of drive transmission is equipped with a tension device, a fully enclosed protective cover and a warning sign.

12. Automatic control system

The control system is equipped with high quality imported PLC, high material level and low material level monitoring device; There are two models, manual and automatic, on the control panel;

Under manual model, every action can be controlled separately;

Under automatic model, main motor and oil pump motor are started first; when the detector for the high material level send back a signal and the pressure of oil pumping system reaches to the proper pressure, the two rollers get engaged automatically, then the motor driving the feeding roller start, and in the meantime, the blocking gate opens, the machine coming to working state;

Several seconds after the low material level sending a signal, the blocking gate and the motor for feeding roller stop automatically, in the meantime, two working rollers get disengaged, the machine coming to stop.

Main technical factors

Capacity: 3.5t/h

Power of main motor: 18.5KW/1pc ×2

Roller size: Φ600×1000(mm)

Speed of roller: 310r/min

Flake thickness: 0.25~0.35mm

Power of main motor for feeding roller: 0.55KW

Speed of feeding roller: Stepless speed chang

Power of main motor for oil pump: 2.2KW

Pressure of oil pumping system: 3.0~4.0Mpa(Depending on the output)

Size: 1953×1669(3078 for counting the motors)×1394(mm)(length × width × height)

Weight: Nearly 7 ton in total.

.png)

.png)